Frequently Asked Questions (FAQs) About Gauged Porcelain Panels

If you have questions about Gauged Porcelain Panels and Slabs, you've come to the right place for answers. Here are questions of particular interest to designers and specifiers. If you don't find the answer to your question, please let us know immediately!

Questions About Gauged Porcelain Tile Panels vs. Slabs:

- What's the difference between a porcelain panel and a porcelain slab?

- When should I specify a panel vs. a slab for a project?

- What are the benefits of using large-format porcelain panels?

FAQs About Design and Aesthetics:

- How realistically do GPPS replicate marble, concrete, or wood? Are the patterns repetitive? Can you create visual continuity?

- How seamless can I make a surface with GPPs? Can I install GPT panels without grout lines?

- How do GPT Panels compare in price and performance to natural stone or quartz?

- What Gauged Porcelain Panel finishes are available?

Questions About Specifying and Installing Gauged Porcelain Panels/Slabs:

- How do I choose the right thickness for my project? (3.5mm, 6mm, 12mm, etc.)

- What are the panel size options?

- What substrate prep is required?

- Can GPPs be installed over existing tile or drywall?

- Are special tools or adhesives required?

- Where can I find qualified installers?

- Are there TCNA or ANSI installation standards?

Technical & Performance FAQs for GPPs:

- Are GPPs strong enough for commercial floor use or heavy foot traffic?

- Do GPPs contribute to LEED credits or meet green building standards?

- What are the slip resistance ratings (DCOF)?

- What is the lifecycle or warranty of GPPs?

Questions About Gauged Porcelain Panels vs. Slabs

What’s the difference between a porcelain panel and a porcelain slab?

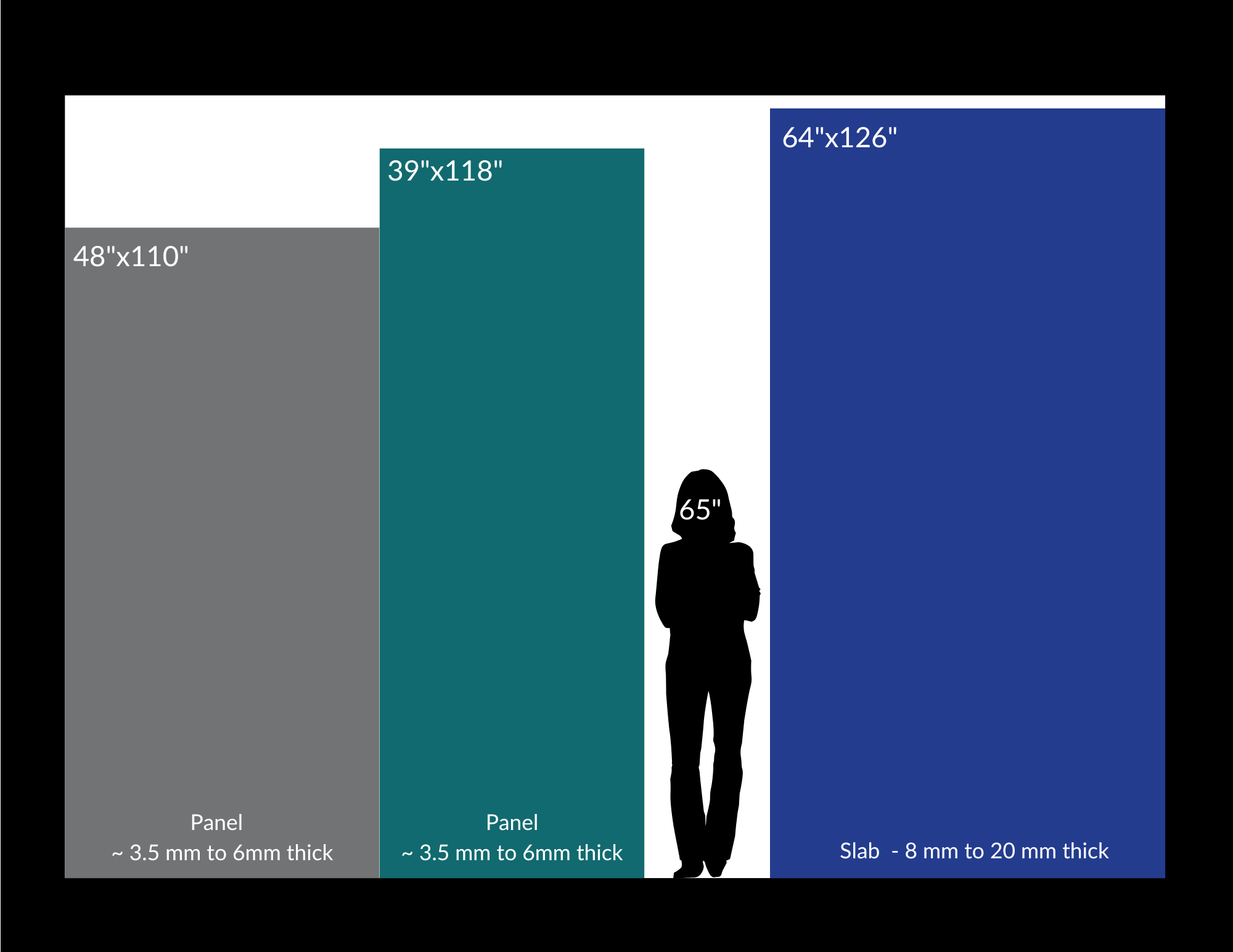

The difference mainly lies in the thickness, weight, and intended use.

Porcelain Panels

Porcelain Panels are thin (typically 3.5mm to 6mm) and panel sizes range between 48"x110" and 39"x118". Panels are lightweight and developed for wall and floor coverings. They’re easier to transport, cut, and install—especially in renovations.

Porcelain Panels are always available with rectified edges and consistent caliber, guaranteeing minimal grout joints, as small as 1/32" for drywall applications.

Porcelain Slabs

Porcelain Slabs are thicker (8mm to 20mm), most often in sizes 60"x120"+. These are ideal for countertop fabrication because the size minimizes waste and allows for larger pieces with fewer joints. They are heavier, and require specialized fabrication and handling, similar to natural stone.

Slabs typically come with natural edges unless rectified by the manufacturer. If used for flooring or wall installations without prior rectification, a wider grout joint (up to 1/4") is needed.

Number of Faces per SKU

A key difference is the number of faces per SKU. Slabs often have one face or a bookmatch design, since they’re meant for fabrication. Panels, designed for surface applications, usually have 3–16 faces to ensure a natural variation across walls or floors.

When should I specify a gauged porcelain panel vs. a slab for a project?

Panels

Use panels (3.5–6mm) for walls, feature walls, fireplaces, backsplashes, floor coverings, and lightweight furniture.

Slabs

Choose slabs (8–20mm) for countertops and areas needing structural depth.

Slabs in 6mm+ can also be used for floor and wall installations, but their only advantage is when the area to be covered is smaller than the slab. This allows the panel to be cut to size for joint-free installation. If joints are used, replacing slabs with panels can save 30–40% in labor and materials.

Many national flooring contractors agree: the push for “no grout” designs increases labor and prep costs dramatically. A precise substrate is hard to guarantee in real-world construction.

Designing with joints allows flexibility and better results.

What are the benefits of using large-format porcelain panels?

Large-format gauged porcelain panels offer you the benefit of a Seamless Look. Large panels mean fewer grout lines which, in turn, offer a cleaner, more modern finish.

For example, a typical 3'x5'x9' shower would have 80 grout joints with 12"x24" tiles, and 16 joints with 24"x48". When you use gauged porcelain tile panels, you would only have 2 grout joints. And 0 with slabs.

Other benefits include:

• Easy to Clean: Fewer joints reduce maintenance and increase hygiene.

• Lightweight: Easier to install, even over existing surfaces—perfect for remodels.

• Durable: Resistant to stains, heat, UV, and water.

• Versatile: Great for walls, floors, countertops, furniture, and fireplaces.

• Eco-Friendly: Lighter products = lower shipping costs and environmental footprint.

GPPs are non-porous, fire-resistant, and UV-stable, making them perfect for high-moisture areas, exteriors, and heat-prone surfaces.

FAQs About Design and Aesthetics

How realistically do GPPS replicate marble, concrete, or wood? Are the patterns repetitive?

Yes. GPPs use high-definition digital printing to replicate natural materials with incredible realism. Furthermore, many collections feature pattern variation to minimize repetition. Combine those stunning, large-format patterns with very large panels and slabs and the result makes a strong design statement.

You can definitely use the same panel across walls, floors, and countertops for visual continuity. GPPs are engineered for multi-surface use, making them ideal for seamless transitions between vertical and horizontal planes.

How seamless can I make a surface with GPPs? Can I install GPT panels without grout lines?

GPPs come in large-format sizes (up to 5' x 10' or more), significantly reducing grout lines and creating clean, continuous surfaces for walls, floors, and more.

You cannot install GPT panels without grout lines. Grout lines are required—even if minimal. GPT Panels need space to expand and contract, and grout joints help prevent failure, absorb substrate imperfections, and allow easier panel replacement if needed.

Here's why it is important to always include joints when designing with porcelain. Grout joints are critical:

• They allow for structural movement, help reduce stress on tiles, and facilitate drainage in wet areas.

• While seamless looks are popular, proper installation requires a 1–2mm joint.

• Requesting “no joints” may lead to installation problems, delays, or voided warranties.

How do GPT Panels compare in price and performance to natural stone or quartz?

GPT panels are usually more cost-effective and have better performance than Natural Stone or Quartz. More specifically,

• Material Cost: Quartz is generally 50%+ more expensive than GPTP. Most Natural Stone products start at over 200% of the cost of GPTP; unique luxury stone products easily cost even more. One slab could cost more than 10 times one GPTP. However GPT Slabs are somewhat similar to natural stone or quartz prices.

• Labor: Lightweight nature of the panels makes installation easier and faster.

• Performance: No sealing required, zero porosity; high chemical and moisture resistance.

• Outdoor Friendly: GPT panels can be installed outdoors whereas Quartz cannot. Natural Stone can be used outdoors, but is not recommended as, in most cases, it will experience changes over time from weather exposure.

• Aesthetic: Advanced printing and texture replicate high-end natural materials beautifully.

What Gauged Porcelain Panel finishes are available?

GPPs are available in polished, matte, honed, and textured finishes, offering design flexibility for various applications and slip resistance needs.

Frequently Asked Questions About Specifying and Installing Gauged Porcelain Panels/Slabs:

How do I choose the right thickness of gauged porcelain tile for my project? (3.5mm, 6mm, 12mm, etc.)

• 3.5mm – Best for indoor and outdoor walls, ceilings, and some residential floors with proper support. This gauged porcelain product is extremely flexible and lightweight—ideal for tall walls and curved surfaces.

• 5–6mm – Great for all floors (residential or commercial), wall cladding, and furniture applications. This thickness balances strength and versatility.

• 12mm and above – Best for countertops, vanities, and heavy-use this thickness in areas where extra thickness is required.

Choosing the right thickness helps ensure better performance, lower cost, and easier installation. If you are unsure, please reach out to us for project-specific advice.

What are the panel size options?

Sizes typically range from 30" x 60" to over 60" x 120". Custom sizes may also be available depending on the manufacturer.

Ultra-thin panels are typically available in the following sizes:

- 48” x 102”

- 48” x 110”

- 39” x 118”

Gauged porcelain slabs, on the other hand, generally range from 8 mm to 20 mm and are most commonly available in larger formats such as 60”+ x 120”+.

What substrate prep is required for Gauged Porcelain Panels/Slabs?

Substrates must be flat, clean, dry, and structurally sound. Lippage tolerances are more stringent for GPPs than standard tile.

Can GPPs be installed over existing tile or drywall?

Yes, GPPs can be installed over existing tile or drywall if the substrate meets flatness and structural requirements. GPPs are ideal for renovations due to their lightweight profile.

Are special tools or adhesives required to install Gauged Porcelain Panels?

Yes. GPPs require specialty tools such as large-format suction cups, scoring systems, and approved mortars and trowel techniques.

Where can I find qualified installers?

Look for installers trained and certified in GPP handling by organizations such as NTCA or manufacturers with approved training programs. Porcelain Concepts sponsors NTCA training sessions with installers in the SouthWest Florida region.

>> See NTCA Interior Gauged Porcelain Tile Panels/Slab Training - 7/31/25

>> See NTCA Gauged Porcelain Tile Panels/Slab Training

Are there TCNA or ANSI installation standards?

Yes. Refer to the TCNA Handbook for Ceramic, Glass, and Stone Tile Installation and ANSI A108.19 American National Standard Specifications for Gauged Porcelain Tiles and Tile Panels/Slabs Specifications – July 2022 for specific guidelines on installing GPPs.

Technical & Performance FAQs for GPPs

Are GPPs strong enough for commercial floor use or heavy foot traffic?

Yes.Gauged Porcelain Panels with a thickness of 6mm or more are approved for commercial flooring and meet strict durability and impact standards.

Do GPPs contribute to LEED credits or meet green building standards?

Many GPPs are Greenguard-certified, low-VOC, and manufactured sustainably—contributing to LEED points and green building goals.

What are the slip resistance ratings (DCOF)?

Slip resistance varies by finish. Check each product’s Dynamic Coefficient of Friction (DCOF) rating to ensure it meets code requirements.

What is the lifecycle or warranty of GPPs?

GPPs offer excellent long-term durability and often come with warranties ranging from 10–25 years depending on application and manufacturer.